Sp 220 Clear Base – WB

14 August 2019

Xp 30 Clear Base – WB

15 August 2019Gs 601 Fine Mesh Clear Base – WB

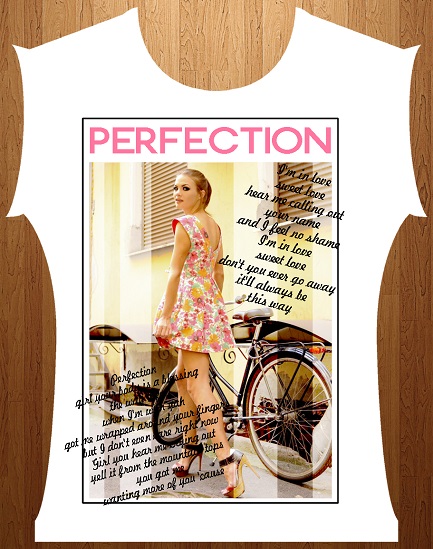

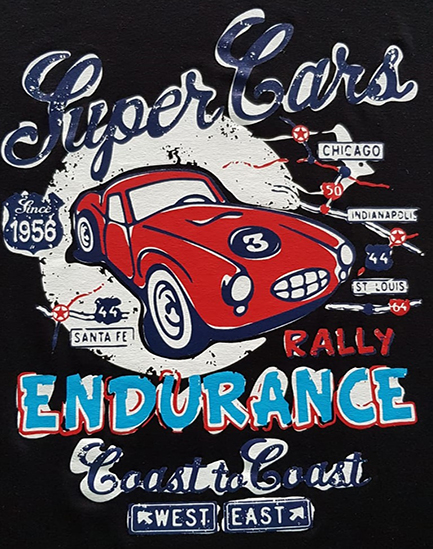

Elastic and soft touching clear base for photographic and heat transfer printings.

Technical Data Sheet

Safety Data Sheet

Description

Elastic and soft touching clear base for photographic and heat transfer printings

Propriétés physiques – chimiques

| Appearance | Clear Base |

| pH | 7-7.5 |

| Type of Fabric | White and Light Colored Cotton and Cotton-Polyester Blend Fabrics |

| Screen | 77 cm/195 inch Mesh 48 micron Silk – 120 cm/305 inch Mesh 34 micron Silk |

| Squeegee | 67 Shore V Type |

| Curing | 160 o C / 320 F – 1,5 minute |

| Washing | 60 o C / 140 F – 1200 rpm – 5 Washes |

| Cleaning of Screen | Water and Sponge |

Application

In order to have more covering, elasticity, color productivity in white and light colored fabrics double print is advised with flash cureTo print on dark colored cotton fabrics, SP 240 – Snow White – WB, GS 603 Fine Mesh Clear White – WB or XP 50 White – WB should be used as underbaseTo print on polyester fabrics which may cause dye migration, SP 230 Anti Migration – WB should be printed as underbaseTo color GS 601 Fine Mesh Clear Base – WB, FA Series (1-5%) or FR Series (5-15%) pigments can be addedTo reduce the viscosity GS 600 Regulator – WB (1-3%) can be used

Pour colorer la base transparente GS 601 à maillage fin, vous pouvez ajouter des pigments WB, FA Series (1-5%) ou FR Series (5-15%).

Pour réduire la viscosité, vous pouvez utiliser le régulateur GS 600 – WB (1-3%)

Rapports

Safety And Storage

It does not contain harmful substances for inhalation and skin when used. However in case of contact tosensitive organs, such as eyes or mouth wash with plenty of water. If necessary, medical assistance is advised.Keep containers dry and tightly closed. Store in a ventilated place between (+5)-(+30) °C/(+41)-(+86)˚F oftemperature.It should be consumed within 12 months after the production date.

Packing

8 kg – 30 kg – 60 kg

1 Gal – 5 Gal – 15 Gal

Reviews

There are no reviews yet.